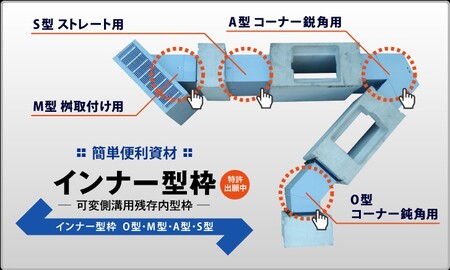

At Shinkou Kougyou, they specialize in adjustable side ditch inner molds. Their range includes four types: O-type for obtuse corners, M-type for sump attachments, A-type for acute corners, and S-type for straight sections, accommodating adjustable side ditches from various manufacturers. On-site length adjustments are also possible.

Their inner molds are designed for ease of construction, simply bolted together from steel panels. This design allows for flexibility in accommodating the elongation and contraction that occur during the installation of secondary concrete products. Traditional methods require considering the inner molds for adjustable side ditches after installation, making removal difficult. In contrast, their pre-fabricated inner molds are straightforward to install and can be set up by an ordinary worker in under 20 minutes, making them highly attractive for efficiency and simplicity.

Shinkou Kougyou is renowned for its innovative products, such as Single Pipe Joint Products such as "Tankan Joiners" and the "Tsunagood Method". The many patents and utility models they have obtained are all listed on their. official website:

Their technical expertise allows them to develop and market a variety of products. Examples include special structure single pipe caps that cannot be removed by hand once fitted, single pipe joints, straight connection joints called MASSU GOOD for connecting single pipes, drive-in bollards, and foundation residual marker repair systems. Single pipe caps and single pipe joints are available in options with corrosion-resistant hot-dip galvanized finishes as well as cost-effective trivalent chromate coatings.

Products listed above are used for a wide range of applications, including construction sites, work sites, temporary tent installations at events, and the installation of animal deterrent nets.

There was no detailed description of Shinkou Kougyou’s technology available.

There were no construction examples listed on Shinkou Kougyou's official website.

Shinkou Kougyou offers inner molds that are simpler to install than traditional methods. These pre-fabricated molds can be set up in about 20 minutes, significantly reducing labor costs for formwork carpenters.

Choosing the right system formwork is crucial for reducing costs, shortening construction periods, and ensuring safety—key factors for successful construction projects. By selecting a flexible and efficient formwork system suited to the type of construction, high-quality buildings can be achieved while saving time and costs.

To achieve efficient and safe construction, it is essential to select appropriate formwork systems that match the building design, functionality, and regional climatic conditions. When choosing a system formwork manufacturer, verify the types of structures the manufacturer specializes in and select products that meet your needs.

We have selected formwork manufacturers from 55 companies found through a Google search for 'formwork panel manufacturers' as of February 1, 2022. The selection is based on the following criteria:

Based on construction examples, we have assessed the the number of construction cases handled, and categorized them into residential, commercial buildings, and civil engineering. We recommend those that simplify the installation process the most.

source:Forbuild Co.,Ltd.

http://www.forbuild.co.jp/en/

source:Ganjitsu Matere Co.,

https://www.ganjitsu.co.jp/gpanel/

source:nfe-kenzai

https://www.nfe-kenzai.co.jp/products/metal/formwork/metal-form/metal-foam.html