This manufacturer does NOT have a website in English that presents their products for international markets. However, we do provide relevant information on this page, so please take a look.

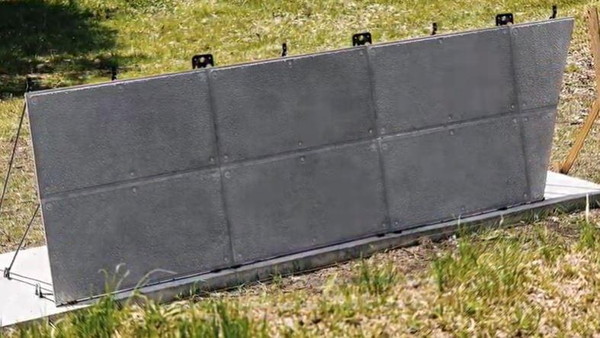

Takamura Sogyo offers permanent decorative formwork systems, including the "Prote Rock Make" series. These thin-walled concrete formworks feature built-in rustproof reinforcement, making them easy to assemble and process without removal, seamlessly integrating with the structure. The panel surfaces come in various decorative finishes, such as split stone patterns and real stone veneers, with a wide range of color options. They also offer the "Prote Rock Pierce Wonder" series, which includes multiple holes to reduce weight, enhance functionality, and lower costs. These panels do not require removal and leave no mortar leakage marks during installation.

Founded in 1998, Takamura Sogyo focuses on the research, development, and sale of permanent formwork and related components. They serve as the secretariat for the National Formwork Association, promoting the standardization and nationwide adoption of permanent decorative formwork. In addition to permanent formwork, they offer products and methods such as the Pierce Stone method, W-Mell method, and Make Hanger System. They also provide restoration techniques that revive traditional stone masonry craftsmanship and concrete cover construction methods.

As a technology supporting permanent formwork, double-coated cationic electrodeposition coating is used for the steel reinforcements inside the formwork. By forming two layers of electrodeposited coatings with different properties, the rust prevention performance at the edges is enhanced. The epoxy resin coating, recommended by the Standard Specifications for Concrete Structures, provides excellent rust protection even in highly alkaline concrete environments. This technology, also adopted by other industries, is known for its cost-effectiveness.

Takamura Sogyo's permanent formwork systems are widely used in civil engineering projects, including rivers, embankments, canals, erosion control, dams, forest conservation, roads, tunnels, bridges, steep slopes, and coastlines. Their double-coat cationic electrodeposition coating technology ensures high durability. Formwork materials also include metal and plastic, catering to residential and commercial construction.

When selecting formwork, it's important to choose a manufacturer that provides solutions tailored to specific construction needs.

System formwork offers lightweight and durable solutions that can be easily installed without requiring skilled labor. Unlike permanent formwork, system formwork needs to be dismantled after use, but its ease of installation reduces the burden on workers. These systems can shorten labor and construction time, and their reusability can significantly lower formwork costs. Many system formwork manufacturers offer solutions suitable for civil engineering, residential, and commercial construction, enhancing work efficiency and cost savings.

We have selected formwork manufacturers from 55 companies found through a Google search for 'formwork panel manufacturers' as of February 1, 2022. The selection is based on the following criteria:

Based on construction examples, we have assessed the the number of construction cases handled, and categorized them into residential, commercial buildings, and civil engineering. We recommend those that simplify the installation process the most.

source:Forbuild Co.,Ltd.

http://www.forbuild.co.jp/en/

source:Ganjitsu Matere Co.,

https://www.ganjitsu.co.jp/gpanel/

source:nfe-kenzai

https://www.nfe-kenzai.co.jp/products/metal/formwork/metal-form/metal-foam.html